The Whole House Approach for Radiant Heating

Our company SA Air Conditioning bases its home comfort systems largely on heating methods imported from Europe, where regulatory conditions and the scarcity of fossil fuels have led to the development of the world’s most sophisticated and energy efficient technology available today.

Europeans have enjoyed the quality and comfort of radiant heating for more than 30 years, perfecting not only the technology but the installation methods also.

Rather than viewing each mechanical component of a home separately, Europeans integrate all components into one combined system, providing homeowners the ultimate in quality, comfort, safety and efficiency.

This is called the whole house approach.

The Whole House Approach

Each house is a system of finely-tuned, integrated parts.

When functioning at peak performance, each component works in unison.

On the other hand, a weakness in just one component can compromise the comfort and quality of an entire home.

For example, failing to insulate a home using the best methods and materials properly can result in compromised performance in the entire heating system, from the boiler’s ability to generate heat efficiently to the chimney’s ability to exhaust toxic gases like carbon monoxide.

The performance of each and every component depends on their integration into one singular system, the whole house.

The Physics of Radiant Heat

Radiant heat travels in all directions.

Much like the heat of the sun, radiant systems heat objects and people, not just the surrounding air.

Think about being outside on a freezing 20-degree day and walking on the shady side of the street.

When you go to the sunny-side of the street you suddenly feel warmer.

When the floor is heated from the water in the tubing, the floor becomes the radiator and releases heat waves to your body and the surrounding objects, giving the sensation and comfort of warmth.

This simple principle allows temperatures in a radiant-heated room to be set lower, lowering fuel consumption and actually improving comfort.

In a properly installed radiant heating system, floor temperatures rise to no more than 85 degrees. This assures maximum comfort safety, and protects the floors from damage due to drying.

Temperatures above this can cause overheating, sweating of feet and decreased system efficiency.

Designing the system

A well-engineered radiant system should be designed to operate using lower water temperatures, maximizing overall efficiency and comfort.

Designing a system requires careful analysis of the many factors that effect heat output.

These factors include:

Water temperature

Tube spacing

Floor covering

Floor surface area

Insulation and ventilation

Outdoor temperatures

Equipment (boiler size, etc)

While most of these factors can be controlled, one factor that usually can’t be is the size of the floor surface.

Depending on the heat-loss of the room, the possibility exists that there may not be enough floor surface-area to heat the room sufficiently.

In this is the case, walls or ceilings can be utilized for radiant heat by installing a climate panel or Thermalboard system.

Tubing:

The most widely used tubing in Europe is called PEX (cross-linked polyethylene).

This flexible plastic tubing was originally designed for the telecommunications industry to lay the trans-Atlantic cable.

PEX has been in use for over 30 years, and as a result of rigid, ongoing testing, it has been shown to have a life expectancy of over 200 years.

PEX tubing is becoming the material of choice in the U.S., versus rubber tubing, which is prone to rapid deterioration.

Another type of tubing that is catching on is PEOC made of Dowlex PE-RT resins.

It is a flexible, easy to handle, five layer tubing with a built-in oxygen barrier.

Boilers – Heating the water:

There are a variety of ways in which to heat the water for your radiant system:

Boilers

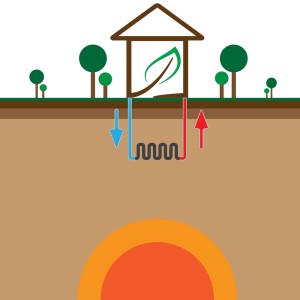

Ground Source Heat Pumps

Wood Boilers

Dedicated Water Heaters

Important Considerations:

The device should be able to withstand lower water temperatures associated with radiant heat. If not, systems or provisions should be made to address this issue.

Offer the lowest possible operating cost

Be clean-burning with low emissions.

Have a large water storage capacity to prevent short cycling (unless it has a modulating burner)

Be easy to service

Different Methods For Different Circumstances

Depending on a home’s structural design, two methods for installing radiant heat are generally employed: wet and dry systems.

Wet Systems:

Wet systems require the tubing to be embedded in concrete. Wet systems are usually found in basements, garages or slab-on-grade construction.

In some living areas, tubing is attached to the top of the sub-floor and then covered with a layer of lightweight concrete.

The benefit to this system comes with its high levels of heat output.

Its disadvantages, however, include:

Installation of hardwood floors become more difficult

Requires a minimum of 1-1/2″ inches of height

Moisture curing can be a problem, compromising the integrity of the flooring

Weight of concrete sometimes requires additional framing

Dry Systems:

Above the sub-floor:

Tubing can be installed on top of sub-floor with aluminum plates and plywood strips, called sleepers.

Dry systems such as these allow finished floor to be installed directly over the tubing.

A method superior to the sleeper system is the climate panel system, consisting of ½”inch plywood, seven or ten inches wide and 4 feet in length.

The panels are equipped with aluminum bonded to the underside. There is a groove in the center that accommodates PEX tubing.

Another product is Thermalboard. A 5/8” thick medium density fiberboard covered with aluminum and a groove that accommodates the tubing.

These panels can be applied on top of the sub-floor or a concrete floor, requiring only 1/2″ – 5/8” in height. The finished floor is applied directly on top of this system.

Advantages:

Excellent heat output

Requires a minimum of 1-1/2″ inches of height

Lightweight and low profile, no additional framing needed

Tubing is visible when nailing finished flooring

No moisture problems

Below the sub-floor:

Another dry method is tubing stapled beneath the subfloor with aluminum heat transfer plates.

This method enjoys most of the advantages of the top-of-the-floor system, except that heat output is lower due to the extra layer of flooring the heat has to travel through.

When used in new construction, care should be taken to avoid any punctures to the tubing.

This is not a problem for a competent flooring company.

Another commonly used dry method we don’t recommend is installing the tubing beneath the sub-floor with no aluminum heat transfer plates.

Because there is little thermal contact of the tubing to the floor, water temperatures have to be increased.

The overall performance of these systems can be very disappointing, especially in colder weather.

The exception to this rule is when you only want to warm the floor surface or want to supplement an existing heat source.

Mixing Valves:

Water temperatures created by heating boilers are usually in the 180-degree F range and are too hot for radiant heat applications.

Excessive temperatures can cause overheating of the space and damage to floors.

An effective way to lower the water temperature is by the use of a mixing valve.

Some mixing valves are set to a fixed temperature but the preferred method is a motorized, modulating valve.

These motorized units provide a higher level of comfort and economy of operation.

Controlling for Comfort

The traditional way to control the comfort of a building is to use a thermostat that turns the circulating pump and boiler on and off as the temperature in the room rises and falls.

The disadvantage of this method comes with the wide fluctuation temperatures, which often results in the feeling of being too hot or too cold.

This on/off strategy may also contribute to drying the floors.

Another method that has proven itself in Europe is to run the circulating pump continuously and vary the temperature of the water.

This is accomplished by using an outdoor thermostat that can increase the temperature of the water circulating through the floor as the outdoor temperature drops, and will decrease the temperature as outdoor temperatures rise.

This strategy puts just the right amount of heat into the house, eliminating wide temperature swings.

The difference is likened to stop and go city driving versus highway driving with cruise control.

The average water temperature in a climate controlled system is usually about 30 degrees less than if you were to use the on/off control system.

In addition to superior comfort, floors are better protected and energy savings of up to 25 percent can usually be expected.

Circulators or Zone Valves?

Another advantage of radiant heating is being able to put each room on its own zone, allowing you to control the temperature in various rooms independently.

This can be accomplished by using a circulator or zone valves for each room.

Using multiple circulators will increase electrical consumption by as much as 5 to 10 times versus the use of zone valves in some instances.

A typical circulator uses approximately 85 watts.

On the other hand, zone valve uses only 2 watts of electricity.

There has been the argument that if the circulator fails on a system that has only one circulator you are entirely out of heat.

The upside of radiant heat is that it takes a long time for the temperature to drop to a very uncomfortable level.

By the time this happens, the circulator will usually have been replaced.

Keep circulators to a minimum for maximum efficiency.

Communication is the Key

In order to get the results you should expect from your radiant system, there has to be good communication between the heat source and radiant system.

Rather than have a variety of controls by different manufacturers, systems should be integrated into one in order to avoid wiring and troubleshooting headaches.

Finger-pointing among building contractors is also eliminated if ever a problem arises.

You’ll Wonder How You Lived Without It!

This helpful guide to radiant heating contains the fundamental facts to put you on your way to enjoying warmth like you’ve never experience

for more information @ Air conditioning repair and service in San Antonio